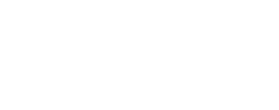

APRON FEEDER

Apron feeders are the most appreciated product of CHAUHAN ENGITECH. These feeders are suitable to control the surge feed created by direct loading by dumpers or wagon loaders. These feeders can be used as surface feeder, where minimum height for feeding is available.

- Coal and Power plant sector

- Cement Industries

- Salt industries

- Minerals

- Brick Clay and ceramics industries

- Minerals

- Food industries

- Paper industries

- Biomass Industries

- Solid waste handling

- Tire and rubber industries

- Industrial Application

Application Area:

- Eff. Belt Width : Up to 3000 mm

- Inclination : Up to 25 Deg.

- Capacity : Up 2500 TPH

Technical specification:

- Effective solution for large capacity

- No Jamming

- Controlled and variable feed rate

- Minimum maintenance and noise

- Long Life

- Designed for dust free operation.

- Highly Efficient and low power requirement.

- Designed to suit & deliver operation requirement with desired capacity

- Comes in various models

Features:

SCREW FEEDER

Screw feeders are useful to assist bin / hopper unloading and in producing uniform / metered feed. The pitch of the screw is kept variable in order to produce uniform draw of material across the entire hopper opening.

The design of a Screw feeder resembles to that of a Screw Conveyor closely but unlike a screw conveyor, a screw feeder is required to be very precise and accurate. While in a Screw conveyor the screw is filled to the extent of 30% to 40%, in a screw feeder the material completely fills the screw. This is the reason why the material is discharged with uniform and controlled rate and the rate can be varied by controlling the speed of rotation of the screw.

Apart from metered feed, one of the important applications for using a Screw Feeder is where the material is dusty or toxic and hence requires an enclosed device.

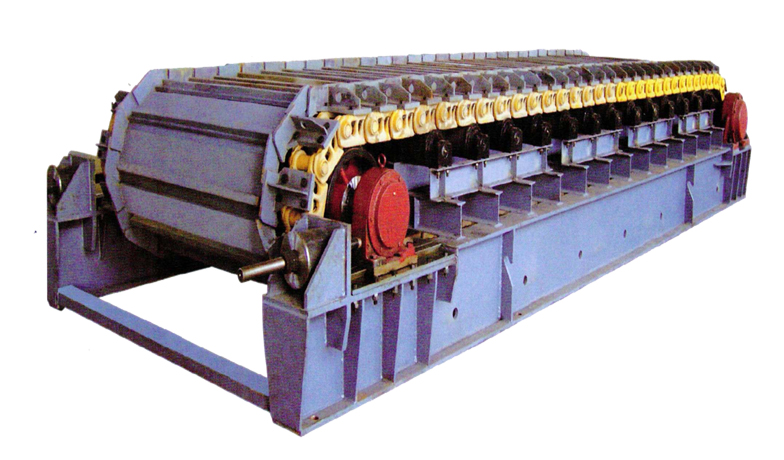

VIBRATORY FEEDER

Sometimes while feeding the dry bulk material to other equipment for further processing or conveying, the material may not move due to the less friction with the surface of the feeder and among the particles. A vibratory feeder in such cases is required to make the material move forward over an incline by producing a vibration effect.

Vibratory Feeders are essentially directional-throw units which consist of a spring-supported horizontal pan vibrated by a direct connected eccentric arm, rotating eccentric weights, an electromagnet or a pneumatic or hydraulic cylinder.

Vibratory Feeders can be equipped to screen the fines ahead of the crusher, and can have easily adjusted feed rate.

ROTARY VALVE FEEDER

Rotary Valves / Feeders are placed under the hoppers or bins to arrange for uniform feed of material to the conveying equipment. Basically it is a volumetric feeding device which helps in applications where the flow rate of the solids needs to be controlled. They can be designed to have approximately 85% volumetric efficiency.

Rotary Valves have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. It can be used to handle bulks even under high temperature. However it should not be used for hard and abrasive materials.

Rotary Valve consists of star type rotor and casing. It is widely used for feeding material into pneumatic conveying line and periodical discharge of material from hopper. Rotary valves help in reducing hazards from explosive dust and volatile material due to air tight construction.